In today’s competitive health and wellness market, brands face a critical challenge: how to grow without compromising quality or speed. Enter co-packing services—the behind-the-scenes partners that turn raw ingredients into shelf-ready products. For supplement brands, this isn’t just about outsourcing—it’s about unlocking scalability, expertise, and precision.

Why Co-Packing Is Redefining Supplement Production

Co-packing, or contract packaging, allows brands to hand off manufacturing, filling, and labeling to specialized partners. The result? Faster time-to-market, reduced overhead, and access to cutting-edge technology. A 2023 industry report revealed that brands using co-packers saw production costs drop by up to 30% while scaling output 2x faster than competitors.

Key Benefits of Partnering with a Co-Packer

- Cost Efficiency: Eliminate machinery investments and facility costs.

- Regulatory Compliance: Navigate FDA guidelines and international standards with partners who know the rules.

- Flexibility: Adjust production volumes without retooling entire operations.

- Expertise: Leverage niche skills, like creating child-resistant packaging for CBD products or nitrogen-flushed pouches for probiotics.

The Rise of Specialized Supplement Co-Packers

Not all co-packers are created equal. The best ones offer tailored solutions:

- Custom Formulation: From vegan capsules to time-release tablets.

- Sustainable Packaging: Compostable blister packs or recyclable bottles.

- Quality Assurance: Third-party testing and batch tracking.

For example, brands prioritizing sustainability might partner with a co-packer using ocean-bound plastic, while those in the nootropics space could require tamper-evident seals.

How to Choose the Right Co-Packing Partner

- Evaluate Their Niche: Do they specialize in powders, liquids, or gummies?

- Audit Compliance Standards: Ensure they meet GMP certifications and your target market’s regulations.

- Test Their Flexibility: Can they handle small batches for launches and scale to 100,000+ units?

This is where regional expertise matters. The Philippines, for instance, has become a hub for supplement co-packing due to its skilled workforce, cost advantages, and strategic proximity to Asian and North American markets.

Why VBC MADE Stands Out in Supplement Co-Packing

Based in the Philippines, Vitamen Beverage Concept, Inc combines precision engineering with a deep understanding of global supplement trends. Their services include:

- Turnkey Solutions: From formulation to final packaging.

- Child-Resistant & Eco-Friendly Options: Align with FDA and EU sustainability mandates.

- Rapid Prototyping: Test packaging designs in days, not weeks.

One brand leveraging VBC MADE reduced its production lead time by 40% while switching to biodegradable pouches—proving that smart partnerships drive growth and innovation.

Ready to Transform Your Supplement Brand?

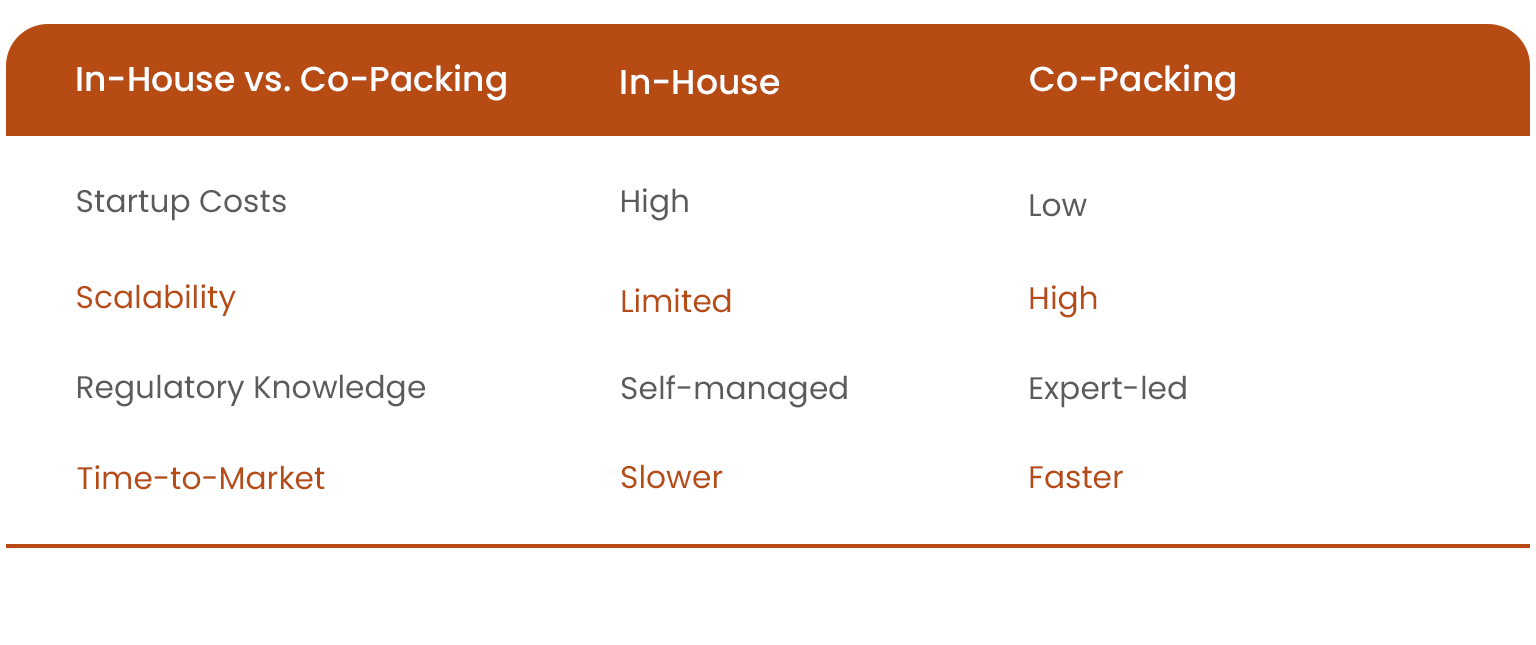

If you’re weighing the risks of in-house production against the agility of co-packing, the choice is clear. Partnering with a toll manufacturer like Vitamen Beverage Concept, Inc., a toll manufacturer in the Philippines, lets you focus on what you do best—building your brand—while experts handle the rest.

Your Next Move:

Visit VBC MADE’s Supplement Packaging Solutions to explore how their co-packing services can elevate your product quality, speed, and market reach.

Phone Number: 09171253990 or 09171093067

Email: askvbc@vbcmade.com

Address: 193 Marcos Highway, Sitio Inuman, Antipolo City and 11 Eulogio Rodriquez Jr. Ave, Pasig City, Metro Manila

Direction: https://maps.app.goo.gl/aHEXgDR8Tm3VrfVPA