Ever asked yourself, “how are vitamins made?” Behind the eye-catching packaging and promising health benefits, a detailed production process is at play. At VBC, your trusted vitamins manufacturer, we go above and beyond to assure the superior quality and effectiveness of our vitamin products. From detailed consultations with clients, to thorough research, and multiple quality checks, our procedures are meticulously managed. In this article, we’re pulling back the curtain on the process of creating vitamins, revealing insights that might just change how you view your daily supplement.

Let’s Clear Some Misconceptions About Vitamin Production, Shall We?

There’s a lot of hearsay out there about how vitamins are made. So, let’s straighten things out a bit:

Misconception 1: Making Vitamins is Just a Mix-and-Match Game

Far from it, folks! To make vitamins, it’s not as simple as tossing a few ingredients together and calling it a day. There’s a science to it – a process that needs precision, thorough testing, and a deep understanding of how different ingredients interact. The type and quality of each ingredient, how they gel together, and even the sequence they’re mixed in can influence the efficacy of the final product.

Misconception 2: All Vitamin Manufacturers are Cut from the Same Cloth

Think again! Not all manufacturers march to the beat of the same drum when it comes to process and quality standards. We at VBC like to stand tall with our robust production protocols that, dare we say, outshine many in the industry.

Misconception 3: All Vitamins are Born Equal

Truth bomb – the quality and potency of vitamins can swing wildly depending on various factors, including the source and quality of raw materials, the production process, and the quality control measures in place. So, it’s super important to pick a vitamin manufacturer, like VBC, that’s committed to delivering top-notch products.

Misconception 4: More is Better

Another misunderstanding is that higher doses of vitamins and minerals are always better. However, optimal health benefits are often achieved at specific dosages. Excessive doses can sometimes lead to harmful effects, known as hypervitaminosis.

A Peek Behind the Curtain: How We Create Vitamins

Ever wondered how to create a vitamin supplement? Strap in for a quick tour of VBC’s vitamin-making journey:

Consultation: Our journey begins with a heart-to-heart with the customer. Here we talk about their goals, the product’s positioning plans, the target audience, and budget considerations. This conversation helps us tailor a strategy to make their product shine in a competitive market.

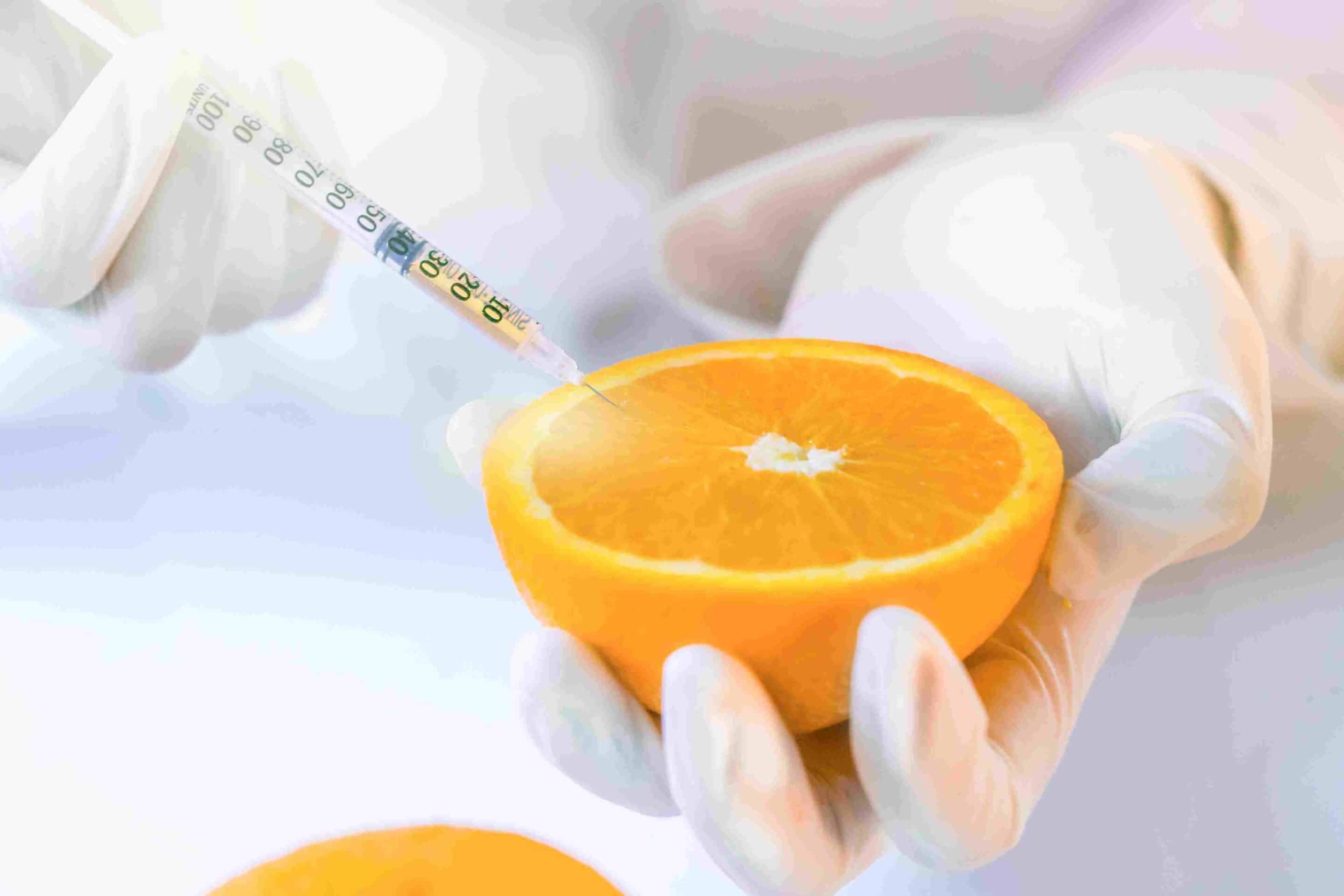

Product Development: If it’s a bespoke vitamin product we’re creating, we dive headfirst into an extensive development process. We scrutinize every ingredient in the new vitamin formula, weighing up the feasibility of the product from a manufacturing and raw material sourcing angle. We turn to science to help us out here, using methods like the angle of repose to examine the flow properties of powdered ingredients and carry out organoleptic analyses on each one.

Compatibility and Stability Checks: Not all ingredients play nice with each other. So, we pore over documents like the Certificate of Analysis (COA) and Material Safety Data Sheet (MSDS) for each ingredient. Our extensive records of stability studies also come in handy when checking the viability of the new formula.

Production Trial: Once we’ve given the product’s production viability the thumbs-up, we roll out a production trial. This helps us check if the product is machinery-friendly before we scale up for a full production run. And of course, the customer gets to see and approve a prototype of the product, ensuring they’re happy with the formula before we proceed.

This step is key in the process of how multivitamins are made, helping us sidestep any expensive hiccups during the production phase. But we’ve got more to share about the production process in the next parts of this article.

Scaling Up Production: Post a successful production trial, we ramp up to full-scale manufacturing. The vitamins are carefully blended, encapsulated, or tableted, and bottled. Throughout this process, constant checks ensure that everything runs like a well-oiled machine.

Quality Assurance and Control: Our quality assurance is built around Good Manufacturing Practices (GMP) to ensure the potency of all the vitamin products that roll off our production line. As soon as the ingredients arrive, our Quality Control (QC) Sampling Technician collects random samples following the square root plus one principle for a representative sample. These samples then undergo rigorous tests for identification, potency, and purity, including an organoleptic analysis.

Quality Checks: Our production process is dotted with quality checks, from the moment the raw materials arrive to the verification of the finished product. These checks ensure that our products are of the highest quality, potency, and efficacy. Only once all test results give us the green light do the ingredients get approved and released for production use. This strict checking continues during the production phase, with the final seal of approval given once the lab confirms the product meets all specifications.

Finished Product: The final act in the process of how vitamins are made? Packaging and labelling. We take special care to ensure our packaging protects the vitamins from moisture, light, and heat, ensuring the product stays fresh long after it leaves our facility. Each bottle carries labels with all the necessary details about the ingredients, dosage, and more. So, there you have it – the journey of a vitamin from our labs to your hands!

Unseen Factors Influencing Vitamin Production

Here are some behind-the-scenes factors that significantly affect vitamin production:

Ingredient Quality: It all starts with top-notch ingredients. At VBC, we’re connected to a wide network of thoroughly vetted global suppliers who provide us with high-quality vitamins and minerals. These suppliers can sometimes offer patented components that can add a unique edge to your products.

Production Process: A fun fact for you – the method used to blend, encapsulate, or tablet the vitamins can greatly influence their effectiveness. Too much exposure to heat or light can degrade them, reducing their potency. That’s why we meticulously control these factors during production.

Vendor Relationships: To maintain consistent production and avoid raw material shortages, a common issue in the industry, we have built strong relationships with multiple ingredient suppliers.

Equipment and Infrastructure: A small machine breakdown can lead to significant production delays. To counter this, we always have backup equipment ready and a skilled maintenance team on hand to resolve any issues quickly.

Next time you take a vitamin, remember the intricate process that went into creating it.

What Sets VBC Apart in the Vitamin Manufacturing Industry

In the vitamin manufacturing world, not all players are created equal. This is especially true when considering the spectrum of quality, transparency, and commitment each manufacturer brings. Here at VBC, our unique blend of expertise, adaptability, and rigorous processes sets us apart.

Our team is not just composed of seasoned experts, but also curious learners who stay ahead of industry trends and research related to vitamin production. We acknowledge the unique needs of every customer and provide flexibility in our processes, creating a product that aligns perfectly with your vision.

We follow strict Good Manufacturing Practice (GMP) guidelines, ensuring consistent high-quality products. We source ingredients from a broad range of trusted suppliers, guaranteeing the potency and quality of your end product.

We also excel in creating tailored product designs, considering the customer’s needs, market competition, and trends. Our expansive network of suppliers enables us to incorporate patented ingredients for a unique touch. And when potential challenges like raw material shortages or machine breakdowns arise, we have proactive strategies to address them.

Peeking behind the curtain of vitamin production has been an intriguing journey. We’ve explored the process, debunked common misconceptions, and shone a light on the often overlooked aspects like rigorous quality checks and the factors influencing the final product.

At VBC, we see this process as more than just creating a product – it’s about crafting an item that adds substantial value to consumers’ lives. Our dedication to quality, backed by a commitment to customer satisfaction, has positioned us as a leader in vitamin production.

In a world where quality is paramount, we are dedicated to delivering the best. As a leading toll manufacturer in the Philippines, we’re here to help turn your vitamin supplement vision into reality.

Remember, as Phil Jackson once said, ‘The strength of the team is each individual member. The strength of each member is the team.’ At VBC, we couldn’t agree more. We’re not just excited but also primed to transform your vision into reality, championing your product’s journey from a mere concept to a complete, market-ready vitamin supplement. So, why wait? Let’s start this incredible journey together today. Reach out to VBC, your trusted partner in vitamin production, and let’s create something extraordinary together. Your success story is just one click away!