Toll manufacturing is a strategic outsourcing arrangement where a company pays a third-party manufacturer to produce goods using the client’s raw materials. This approach offers numerous benefits, including cost savings, access to specialized expertise, and flexibility in production scaling. For small business owners in the Philippines, understanding how toll manufacturing works can be crucial for expanding operations without significant capital investment. In this guide, we’ll explore the key aspects of toll manufacturing and its advantages.

Introduction to Toll Manufacturing

Toll manufacturing involves a client company providing raw materials to a subcontractor, who manufactures the goods for a fee. This setup allows businesses to maintain control over the production inputs while leveraging the specialized capabilities of the manufacturer. Unlike contract manufacturing, where the manufacturer sources the raw materials, toll manufacturing gives clients more control over the quality and sourcing of materials.

The primary difference between toll and contract manufacturing lies in who supplies the raw materials. In toll manufacturing, the client provides the materials, which can be beneficial for maintaining quality standards and ensuring consistency in production. This approach is particularly useful for companies with proprietary materials or specific sourcing requirements.

Benefits of Toll Manufacturing

Toll manufacturing offers several benefits that make it an attractive option for small businesses looking to scale their operations efficiently.

Cost-Effectiveness

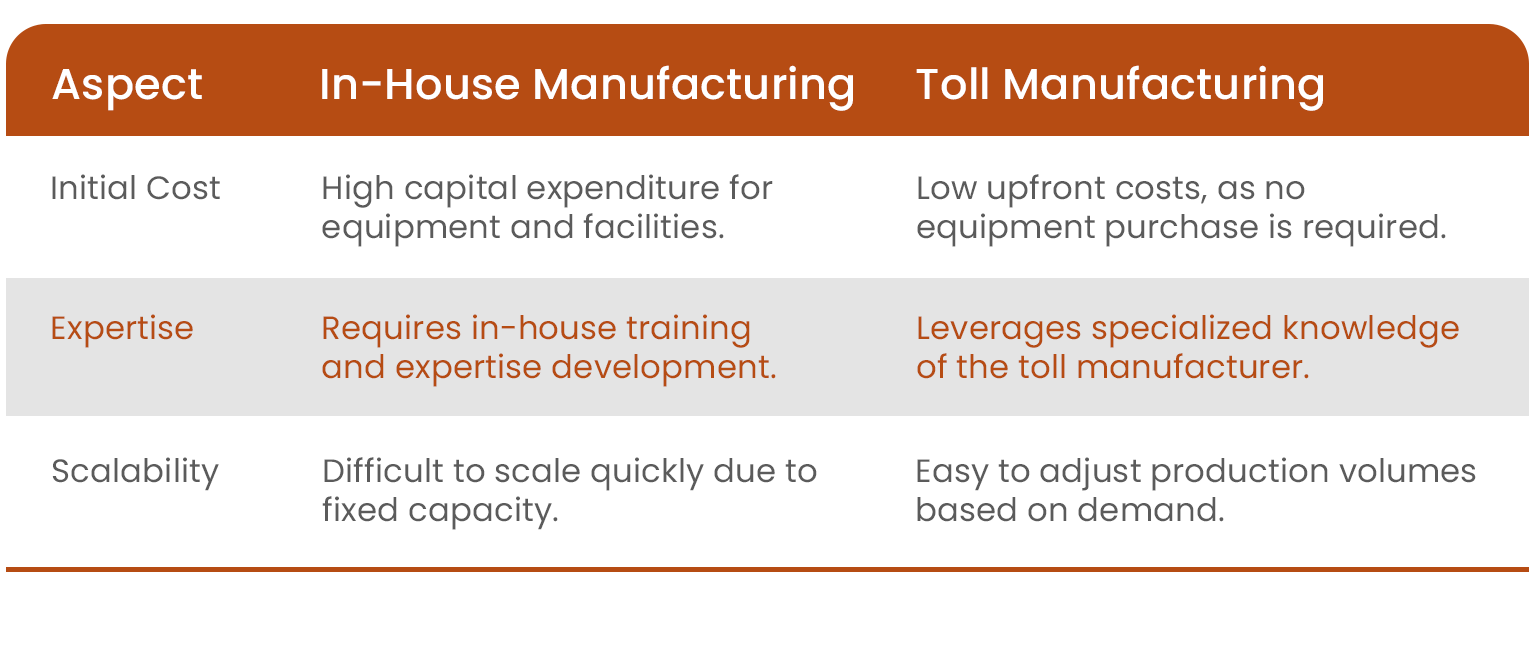

One of the most significant advantages of toll manufacturing is its cost-effectiveness. By outsourcing production, businesses can avoid the substantial capital expenditures required to purchase equipment and set up manufacturing facilities. This approach allows companies to allocate resources more strategically, focusing on core competencies like product development and marketing.

Access to Expertise

Toll manufacturers often possess specialized knowledge and advanced technology that small businesses might not be able to afford on their own. By partnering with these manufacturers, companies can leverage this expertise to improve product quality and efficiency without direct investment in training or equipment.

Flexibility and Scalability

Toll manufacturing provides the flexibility to adjust production volumes quickly based on market demand. This scalability is invaluable for small businesses that need to respond rapidly to changes in consumer preferences or market conditions.

The Toll Manufacturing Process

The process of engaging in toll manufacturing involves several key steps:

- Initial Consultation: The client and the toll manufacturer discuss project requirements, quality standards, and production timelines. This stage is crucial for aligning expectations and ensuring that both parties understand their responsibilities.

- Prototyping and Development: Before full-scale production begins, samples are produced to test the product specifications and ensure they meet the client’s requirements. This step helps identify any potential issues early on.

- Production Planning: The client and manufacturer work together to source materials (if not provided by the client), schedule production, and allocate necessary resources. Effective planning is essential for maintaining efficiency and meeting deadlines.

- Production: The actual manufacturing process takes place using the specialized equipment and expertise of the toll manufacturer. This stage involves adhering to agreed-upon quality standards and production schedules.

- Quality Control: Products are inspected and tested to ensure they meet the required standards. This step is critical for maintaining product quality and client satisfaction.

Packaging and Distribution: Once products pass quality control, they are prepared for packaging and distribution to the market.

Toll Manufacturing Agreements

When engaging in toll manufacturing, it’s essential to have a clear agreement that outlines the scope of work, quality standards, pricing, and payment terms. This agreement should also address intellectual property protection to safeguard the client’s proprietary information.

Scope of Work

The agreement should clearly define the manufacturing tasks and responsibilities of both parties. This includes specifying what materials will be provided by the client and what services will be rendered by the manufacturer.

Quality Standards

Quality standards and inspection procedures must be detailed to ensure that products meet the client’s specifications. This may involve regular audits or quality control checks during production.

Pricing and Payment

The agreement should specify the fees for manufacturing services and the terms of payment. This could include payment schedules, payment methods, and any penalties for late payments.

Intellectual Property Protection

To protect the client’s proprietary information, such as formulas or designs, the agreement should include clauses that safeguard intellectual property rights.

Frequently Asked Questions

1. What are the main advantages of toll manufacturing for small businesses?

The main advantages include cost savings, access to specialized expertise, and flexibility in production scaling. These benefits allow small businesses to enhance their operational efficiency without significant capital investment.

2. How does toll manufacturing differ from contract manufacturing?

Toll manufacturing differs from contract manufacturing primarily in who supplies the raw materials. In toll manufacturing, the client provides the materials, whereas in contract manufacturing, the manufacturer sources them.

3. What industries commonly use toll manufacturing?

Toll manufacturing is commonly used in industries such as electronics, health and wellness, and chemicals. These sectors often require specialized equipment and expertise that can be efficiently outsourced.

Conclusion

Toll manufacturing offers small businesses a strategic way to enhance production capabilities without significant upfront costs. By understanding the process and benefits of toll manufacturing, entrepreneurs can make informed decisions about outsourcing their manufacturing needs. Whether you’re looking to scale production or access specialized expertise, toll manufacturing can be a valuable tool for growth and competitiveness in the Philippines.

Consider exploring toll manufacturing options like Vitamen Beverage Concept, Inc., a toll manufacturer in the Philippines, to boost your business’s efficiency and reach a wider audience. This approach can help you navigate the challenges of production scaling while maintaining control over your products’ quality and sourcing. Contact us today!

Phone Number: 09171253990 or 09171093067

Email: askvbc@vbcmade.com

Address: 193 Marcos Highway, Sitio Inuman, Antipolo City and 11 Eulogio Rodriquez Jr. Ave, Pasig City, Metro Manila

Direction: https://maps.app.goo.gl/aHEXgDR8Tm3VrfVPA