Toll manufacturing is a strategic outsourcing arrangement where a company supplies raw materials to a third-party manufacturer, paying only for the manufacturing services. This approach allows businesses to scale production without investing in new infrastructure. In this guide, we’ll explore the key aspects of toll manufacturing, its benefits, and how it can help small businesses expand their operations efficiently.

Benefits of Toll Manufacturing

Toll manufacturing offers several advantages that make it an attractive option for businesses looking to optimize their production processes:

- Control Over Raw Materials: By supplying the raw materials, companies can ensure that they maintain control over the quality and cost of these inputs. This is particularly important for businesses with proprietary formulas or specific material requirements.

- Cost-Effectiveness: One of the most significant benefits of toll manufacturing is its cost-effectiveness. Businesses can avoid the substantial capital investment required to establish or expand their own manufacturing facilities. This includes costs associated with equipment, labor, and infrastructure maintenance.

- Flexibility: Toll manufacturing allows for easy scaling of production. Whether a company needs to increase or decrease output, the third-party manufacturer can adjust production levels accordingly without the need for significant upfront investments.

How Toll Manufacturing Works

Understanding the process of toll manufacturing is crucial for businesses considering this option:

- Supply of Raw Materials: The client provides all necessary raw materials to the third-party manufacturer. This ensures that the client maintains control over the quality and cost of these materials.

- Manufacturing Process: The toll manufacturer processes the materials according to the client’s specifications. This includes adhering to specific production methods, quality standards, and timelines.

- Payment Structure: The client pays a fee for the manufacturing service. This fee typically covers labor, equipment usage, and other operational costs associated with the production process.

Common Industries Using Toll Manufacturing

Toll manufacturing is utilized across various industries due to its flexibility and cost-effectiveness:

- Consumer Electronics: Companies like Apple use toll manufacturing extensively to produce components and final products. This allows them to maintain high production volumes without investing in additional manufacturing infrastructure.

- Food Processing: Toll manufacturing is useful in the food industry for maintaining proprietary recipes and ensuring consistent quality. Companies can supply their specific ingredients and have them processed according to their formulations.

- Pharmaceuticals: The pharmaceutical industry benefits from toll manufacturing by outsourcing complex production processes. This helps manage regulatory compliance and ensures high-quality products.

Challenges and Considerations

While toll manufacturing offers numerous benefits, there are also challenges and considerations that businesses should be aware of:

- Logistical Challenges: Managing the delivery of raw materials and coordinating production schedules can be complex. Ensuring timely delivery and maintaining inventory levels is crucial to avoid production delays.

- Quality Control: Ensuring that the manufacturer meets quality standards is essential. Regular audits and inspections can help maintain quality control.

- Contractual Agreements: Negotiating favorable contractual terms is important. This includes specifying payment terms, production volumes, and quality standards.

Frequently Asked Questions

1. What is the main difference between toll and contract manufacturing?

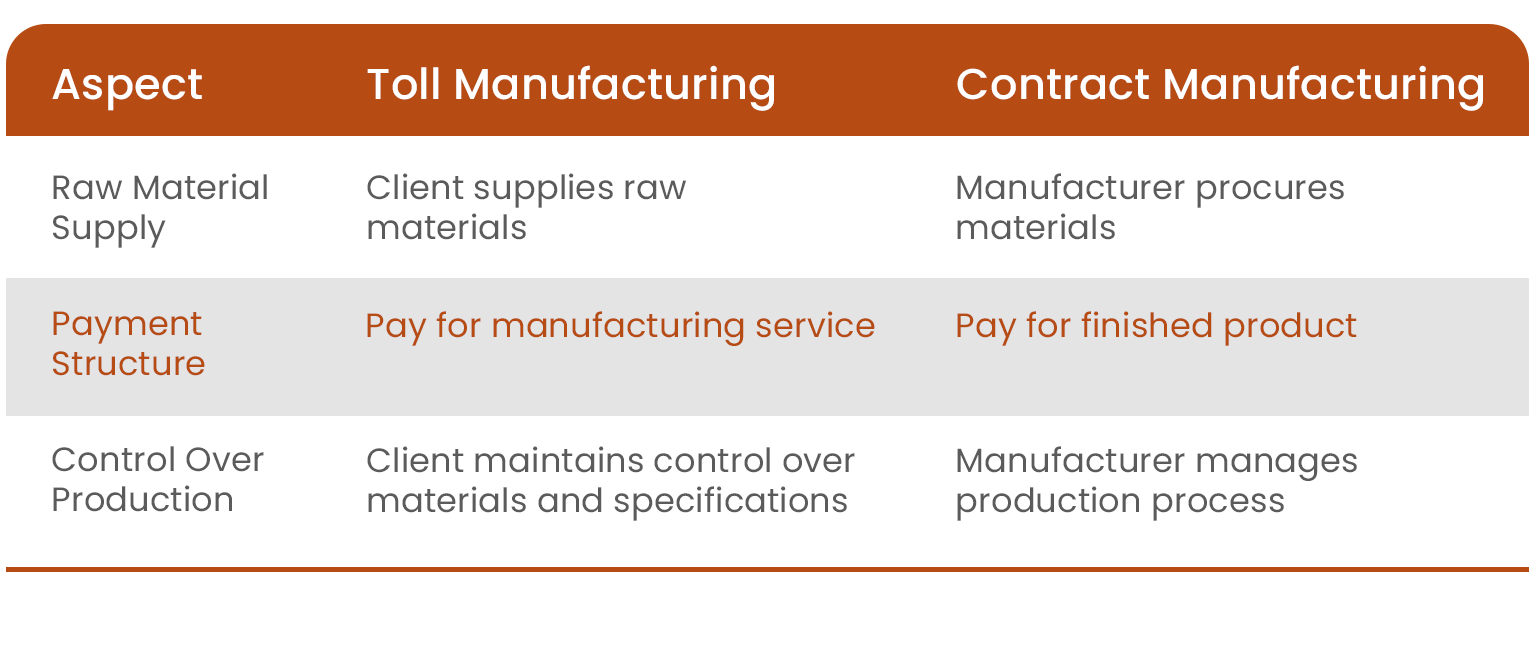

The difference between toll and contract is that toll manufacturing involves the client supplying raw materials, while in contract manufacturing, the manufacturer procures them. This difference impacts the level of control over material costs and quality.

2. How does toll manufacturing help with cost control?

It allows businesses to avoid fluctuations in raw material prices and only pay for manufacturing services. This can significantly reduce operational costs and improve budget predictability.

3. What are the common industries that use toll manufacturing?

Industries like consumer electronics, food processing, and pharmaceuticals frequently use toll manufacturing due to its flexibility and cost-effectiveness.

Conclusion

Toll manufacturing offers small businesses a cost-effective way to scale production while maintaining control over raw materials and quality. By understanding its benefits and challenges, businesses can leverage toll manufacturing to expand their operations efficiently. Consider integrating toll manufacturing into your strategy to enhance your production capabilities without significant capital investment. Whether you’re looking to increase production volume or enter new markets, toll manufacturing can be a strategic move to drive growth and profitability.

This content aims to provide a comprehensive overview of toll manufacturing, addressing both its advantages and challenges, and is designed to engage small business owners seeking to optimize their production processes.

Curious about something? Got a sparkling great new idea for a formulation? You can request a quote here for FREE!