Toll manufacturing offers a strategic way for businesses to outsource production processes, leveraging specialized equipment and expertise without significant capital investments. This approach is particularly beneficial for small businesses seeking to enhance efficiency and reduce costs. In this guide, we’ll explore when a company should consider toll manufacturing and its key benefits.

Introduction

In today’s competitive market, businesses are constantly looking for ways to optimize their operations, reduce costs, and improve product quality. Toll manufacturing provides an attractive solution by allowing companies to focus on their core competencies while outsourcing production to specialized partners. This model is especially appealing to small business owners in the Philippines who are beginners in manufacturing, as it helps them navigate financial constraints and access advanced technology.

Toll manufacturing involves partnering with a third-party manufacturer that processes raw materials or semi-finished goods using their equipment and expertise. This partnership can be tailored to meet specific business needs, whether it’s producing a single component or a complete product. By leveraging toll manufacturing, companies can enhance their production capabilities without the upfront costs associated with purchasing equipment or hiring specialized staff.

Benefits of Toll Manufacturing

Cost Savings

- Reduced Capital Expenditure: By outsourcing production, companies avoid investing in specialized equipment and facilities, which can be a significant financial burden. This is particularly beneficial for small businesses with limited capital resources.

- Lower Labor Costs: Toll manufacturing allows businesses to access skilled workers without the need for full-time employment, reducing labor costs and minimizing the administrative burden of managing a large workforce.

- Predictable Costs: Formal contracts with toll manufacturers ensure clear pricing structures, helping businesses budget more effectively and manage cash flow better.

Specialized Expertise

- Access to Advanced Technology: Toll manufacturers often have the latest equipment and technology, enabling them to produce high-quality products efficiently. This access to advanced technology can significantly improve product quality and consistency.

- Compliance with Regulations: Outsourcing to a reputable toll manufacturer ensures adherence to industry standards and regulations, reducing compliance risks and potential legal liabilities.

Increased Efficiency

- Streamlined Production: By focusing on core business activities while outsourcing production, companies can streamline their operations and improve overall efficiency. This allows businesses to concentrate on product development, marketing, and customer service.

- Scalability: Toll manufacturing allows businesses to easily adjust production volumes to meet market demands, making it ideal for companies experiencing rapid growth or fluctuating demand. This flexibility is crucial in responding quickly to changes in market conditions.

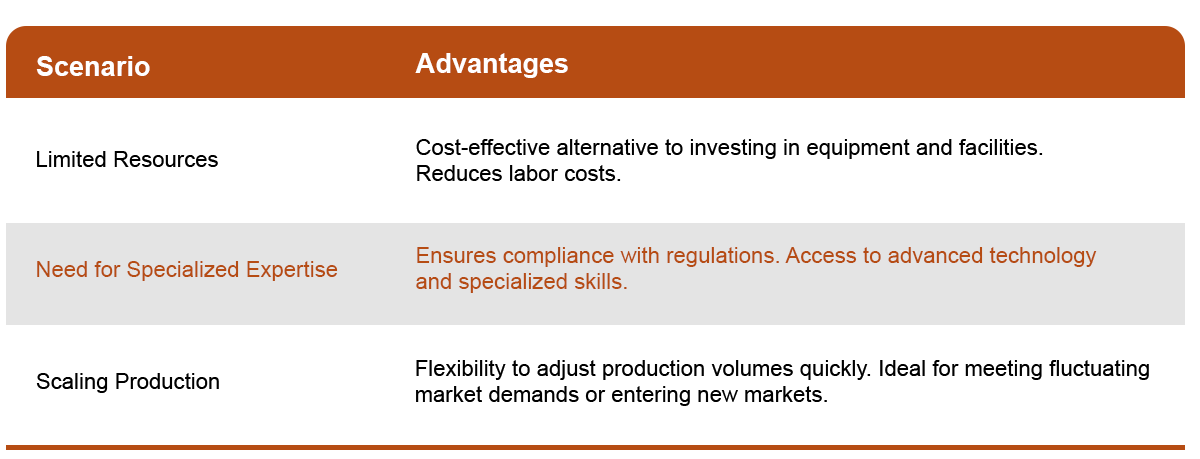

When to Consider Toll Manufacturing

1. Limited Resources

- Financial Constraints: When capital for equipment and facilities is limited, toll manufacturing provides a cost-effective alternative. It allows businesses to allocate resources more effectively, focusing on core activities rather than capital-intensive investments.

- Lack of Specialized Equipment: When in-house capabilities are insufficient, outsourcing to a toll manufacturer can fill the gap. This is particularly useful for producing complex components or products that require specialized machinery.

2. Need for Specialized Expertise

- Regulatory Compliance: When ensuring compliance with industry regulations is crucial, toll manufacturers can provide the necessary expertise. They often have experience navigating complex regulatory environments, ensuring that products meet all required standards.

- Product Customization: When customized product formulations or packaging are required, toll manufacturers can offer tailored solutions. This flexibility is valuable for businesses looking to differentiate their products in the market.

3. Scaling Production

- Market Demand Fluctuations: When production needs to be quickly adjusted to meet changing market demands, toll manufacturing offers flexibility. This allows businesses to ramp up or scale down production rapidly without having to invest in new equipment or hire additional staff.

- Entering New Markets: When expanding into new markets with different regulatory requirements, toll manufacturers can help navigate these challenges. Their expertise in managing diverse regulatory environments can be invaluable for businesses entering new territories.

Frequently Asked Questions

What is Toll Manufacturing?

Toll manufacturing involves outsourcing production to a third-party company that processes materials using their equipment and expertise. This model is often used in industries where specialized equipment or expertise is required.

How Does Toll Manufacturing Save Costs?

By eliminating the need for capital investments in equipment and facilities, and reducing labor costs. Toll manufacturing also provides predictable costs through formal contracts, which helps in budgeting and financial planning.

What Industries Use Toll Manufacturing?

Industries such as pharmaceuticals, food and beverages, and health and wellness commonly use toll manufacturing. These sectors often require specialized equipment and strict regulatory compliance, making toll manufacturing an attractive option.

Case Studies: Success Stories in Toll Manufacturing

Example 1: Pharmaceutical Industry

A pharmaceutical company needed to produce a new medication that required specialized equipment for formulation and packaging. By partnering with a toll manufacturer, they were able to access the necessary technology without a significant upfront investment. This partnership allowed them to bring the product to market quickly while maintaining high quality standards.

Example 2: Food and Beverage Sector

A startup in the food industry wanted to launch a new line of organic products but lacked the facilities to meet the required production volumes. They partnered with a toll manufacturer who had the capacity to produce large quantities while adhering to organic standards. This partnership enabled the startup to meet market demand without investing in new equipment.

Conclusion

Toll manufacturing is a strategic option for businesses looking to enhance production efficiency, reduce costs, and access specialized expertise. By understanding when to leverage toll manufacturing, companies can make informed decisions that drive growth and competitiveness. Whether you’re facing financial constraints or need to scale production quickly, toll manufacturing offers a flexible and cost-effective solution.

If you’re considering toll manufacturing for your business, take the next step by exploring how this model can benefit your operations. For personalized advice and to discuss your specific needs, request a quote today and discover how toll manufacturing can transform your business. Our team is ready to help you navigate the process and ensure that your production goals are met efficiently and effectively.

Phone Number: 09171253990 or 09171093067

Email: askvbc@vbcmade.com

Address: 193 Marcos Highway, Sitio Inuman, Antipolo City and 11 Eulogio Rodriquez Jr. Ave, Pasig City, Metro Manila

Direction: https://maps.app.goo.gl/aHEXgDR8Tm3VrfVPA